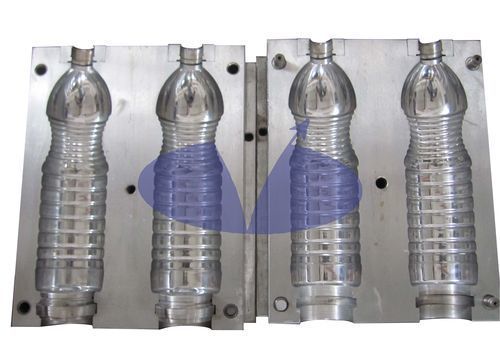

1.2311 Plastic Mould Steel Block

Product Details:

1.2311 Plastic Mould Steel Block Price And Quantity

- 200 Kilograms

- 109 INR/Kilograms

Product Description

Product details

| Minimum Order Quantity | 200 Kilogram |

| Coefficient of thermal expansionat Degree C | 20-700 |

| Cooling | Furnace |

| Hardening Degree C | 840 - 870 |

| Hardness after quenching HRC | 51 |

| Hardness HB | Max 235 |

| Quenching | Polymer or Oil |

| Width | 40 to 700 mm |

| Application | Automobile Industry |

| Shape | Rectangular |

| Technique | 20 to 400 |

| Soft Annealing | 710 - 740 Deg C |

Chemical Composition - (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | Ni | Mo |

| 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 0.030max | 0.030max | 1.80-2.10 | 1.90-1.20 | 0.15-0.35 |

Physical Properties:

| Coefficient of Thermal Expansion at °C | 10m / (m*K) |

| 20-100 | 11.2 |

| 20-200 | 12.8 |

| 20-300 | 13.5 |

| 20-400 | 13.7 |

| 20-500 | 14.3 |

| 20-600 | 14.7 |

| 20-700 | 14.9 |

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 35 |

| 350 | 34 |

| 700 | 33 |

Heat Treatment

| Soft Annealing °C | 710-740 |

| Cooling | Furnace |

| Hardness HB | max. 235 |

| Hardening °C | 840-870 |

| Quenching | Polymer or Oil |

| Hardness after quenching HRC | 51 |

| Tempering°C after quenching | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| HRC | 51.5 | 50.2 | 48 | 46.2 | 43 | 39 | 29 |

Other Products in 'Plastic Mould Steel' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS