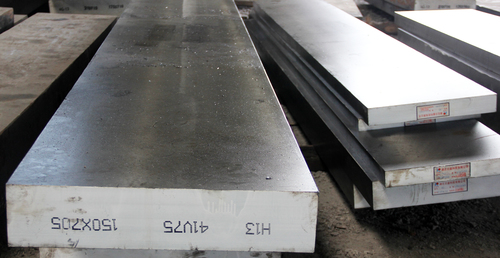

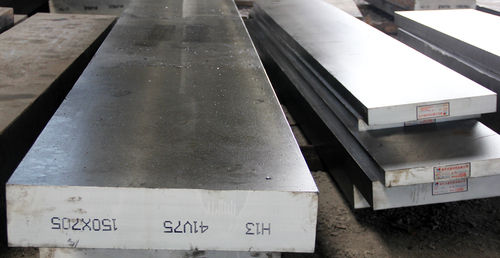

L6 Die Steel

उत्पाद विवरण:

मूल्य और मात्रा

- किलोग्राम/किलोग्राम

- 150

- किलोग्राम/किलोग्राम

व्यापार सूचना

- 50-100 प्रति सप्ताह

- 1 हफ़्ता

उत्पाद विवरण

L6 Die Steel Chemical composition - (Typical analysis in %)

| Standards | DB6 |

| DIN2714 |

| AISI L6 |

| AFNOR | 55NCDVV7 | JIS SKT4 |

| 55iNiCrMoV | C | Si | Mn | P | S | Cr | Ni | Mo | V |

|

| 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | <0.015 | <0.004 | 1.00-1.20 | 1.50-1.80 | 0.45-0.55 | 0.07-0.12 |

| USA | Europe | Germany | China | Japan | India | R.of Korea | Russia |

| AISI/SAE | En | DIN,WNr | GB | JIS | IS | KS | GOST |

| A681 L6 | 55NiCrMoV7 | 56NiCrMoV7 | 5CrNiMo | SKT 4 | T55Ni7Cr4Mo5V1 | STF 4 | 4ChMNFS |

Ventura Alloy and Steels Stocks and Supply L6 Die Steel in India and abroad. DB6 Steel is an extreme pass on steel with high treating resistance and great through-solidifying properties. Its nickel substance has it uncommonly effect safe - a highly recommendable element for vast mallet & press bites the dust alike. This evaluation is generally supplied in toughened condition or extinguished and tempered to 1300 N/mm & a working hardness of 370 to 410 HB (round) or 355 to 400 HB (square, level).

Utilized as standard steel for manufacturing passes on of different kinds, press bites the dust, expulsion kicks the bucket, retainer plates, heavily clad trim bites the dust, hot shear sharpened pieces of steels and instrument holder.

Utilized as standard steel for manufacturing passes on of different kinds, press bites the dust, expulsion kicks the bucket, retainer plates, heavily clad trim bites the dust, hot shear sharpened pieces of steels and instrument holder.

PROCESS ROUTE

EAF+LF+VD+UPSET+FORGED+ANNEALED+ROUGH TURNED FOR ROUNDS/MILLED FOR FLATS+OIL QUENCHED AND DOUBLE TEMPERED+ ROUGH TURNED FOR ROUNDS/MILLED FOR FLATS

STEEL PROPERTIES

The special Hot Work Pre-hardened Steel has great toughness and high wear resistance. DB6 Steel is generally supplied in hard, quenched, tempered and also in annealed condition in special cases.Usually it's working hardness is 360-430 BHN. This steel grade is the upgraded version of DIN 2713 for greater efficiency and performance.

APPLICATION

Dies for Specially Drop and Close Die Forgings for Hammers & Mechanical Presses, Die Moulds,Shoe Blocks, Die Holder, Cassettes, Piston Rods, Cranks, Boaster, Shearing Blades, Tools, plastic moulds Etc.

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at°C | 10 m/(m*K) |

| 20-100 | 12.1 |

| 20-200 | 13.1 |

| 20-300 | 13.2 |

| 20-400 | 13.5 |

| 20-500 | 14..1 |

| 20-600 | 14.3 |

| Thermal Conductivity at °C | W/(m/*K) |

| 20 | 35.0 |

| 350 | 39.0 |

| 700 | 36.0 |

HEAT TREATMENT

| Soft annealing °C | 650-710 |

| Cooling | Furnace |

| Hardness HB | max, 240 |

| Hardening °C | 840-880 /860-900 |

| Quenching | Oil / Air |

| Hardness after quenching HRC | 57 / 55 |

| Tempering °C after quenching | 100 | 200 | 300 | 400 | 450 | 500 | 550 | 600 | 600 |

| in Oil -HRC | 56 | 54 | 52 | 49 | 47 | 46 | 43 | 38 | 34 |

| in Oil -HRC | 54 | 52 | 50 | 47 | 45 | 43 | 40 | 36 | 32 |

Size Range:

- Rounds - 60 To 1000 Mm Dia.

- Blocks - Thickness - 125 To 1000 Mm Max | Width - 130 To 1600 Mm Max.

Hot Work Steel (IND/USA/EUR) अन्य उत्पाद

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें