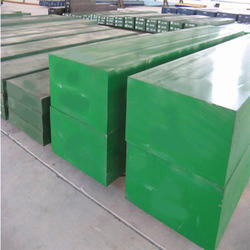

HCHCR D2 Cold Work Tool Steel

Product Details:

HCHCR D2 Cold Work Tool Steel Price And Quantity

- 110.00 - 300.00 INR/Kilograms

- 1000 Kilograms

- 192 INR/Kilograms

HCHCR D2 Cold Work Tool Steel Trade Information

- Mumbai Navashiva

- 50-100 Kilograms Per Week

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

Essentially, the tungsten, manganese, chromium, and molybdenum additions to this HCHCR D2 Cold Work Tool Steel are quite minor alloy additions. This HCHCR D2 Cold Work Tool Steel has a high carbon content, making it relatively inexpensive and providing enough wear resistance for short-run purposes. It is utilized for various kinds of blanking and shaping dies, gauges, collets, etc. When metal is cold, it may be utilized to shape or distort it. It possesses great wear resistance, strength, and hardness, as well as good biting resistance and the capacity to soften when heated.

HCHCR D2 Cold Work Tool Steel Details:

| Minimum Order Quantity | 1000 Kilogram |

| Application | Automobile Industry |

| Soft annealing Degree C | 810-850 |

| Hardness HB | max 230 |

| Cooling | Furnace |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Cold Work Steel (IND/USA/EUR)' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free