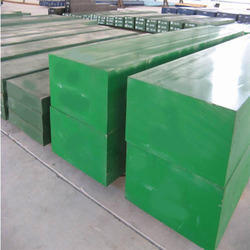

D2 Die Block Steel

उत्पाद विवरण:

D2 डाई ब्लॉक स्टील मूल्य और मात्रा

- किलोग्राम/किलोग्राम

- किलोग्राम/किलोग्राम

- 200

D2 डाई ब्लॉक स्टील व्यापार सूचना

- 50-100 प्रति सप्ताह

- 1 हफ़्ता

उत्पाद विवरण

Carving a niche for our organization, we are engaged in manufacturing and supplying wide gamut of D2 Die Block Steel to our prestigious clients. It is made with highly effective heat treatment process that transmits it great features including brilliant strength, and outstanding performance due to which it has achieved an escalated position in market. Further, it is recommended for Close Die Forgings due to its characteristics of high wear-resistance, extra toughness, high hardness which is achieved with Cr-Ni-Mo-V high graded alloys. D2 Die Block Steel is available in different sized and specifications as per demands of customers.

Technical Specification

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 1.40-1.60 | 0.10-0.60 | 0.20-0.60 | 0.040max | 0.040 max | 11.00-13.00 | 1.65-2.00 | 0.70-0.100 | 0.80-1.20 |

Physical Properties

| Coefficient Conductivity at °C | 10-8W/ (m*K) |

| 20-100 | 10.6 |

| 20-200 | 11.5 |

| 20-300 | 11.8 |

| 20-400 | 12.3 |

| Thermal Conductivity at °C | W(m*k) |

| 20 | 16.7 |

| 350 | 20.5 |

| 700 | 24.2 |

Heat Treatment

| Soft Annealing °C | 840-870 |

| Cooling | Furnace |

| Hardness HB | Max. 250 |

| Stress-relief Annealing °C | Approx. 660-710 |

| Hardening °C | 1000-1050 |

| Quenching | Air, oil salt bath 500-550°C |

| Hardness after Quenching HRC | 63 |

Tempering °C after quenching | 100 | 200 | 300 | 400 | 500 | 525 | 550 | 600 |

HRC | 64 | 61.5 | 58.5 | 58.5 | 59 | 60 | 57 | 50 |

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

कोल्ड वर्क स्टील (IND/USA/EUR) अन्य उत्पाद

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें