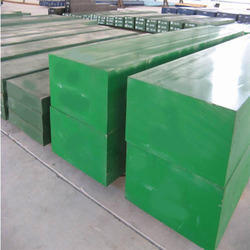

D2 Die Steel

Product Details:

D2 Die Steel Price And Quantity

- 192 INR/Kilograms

- 200 Kilograms

D2 Die Steel Trade Information

- 50-100 Kilograms Per Week

- 1 Week

Product Description

Backed by enthusiasm of our sincere working staff, we are engaged in manufacturing and supplying D2 Die Steel to our honorable clients. It is air hardening, high-carbon, high-chromium tool steel. This steel is heat treatable and machinable in annealed condition. Apart from this, it has wide number of applications including stamping or forming dies, punches, or forming rolls, and tyre shedders. Also, D2 Die Steel is available in different technical specifications as per demands of customers. It is made by our highly skilled professionals, with use of unique tools &technology.

Technical Specification

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 1.40-1.60 | 0.10-0.60 | 0.20-0.60 | 0.040max | 0.040 max | 11.00-13.00 | 1.65-2.00 | 0.70-0.100 | 0.80-1.20 |

Physical Properties

| Thermal Conductivity at °C | W / (m*K) |

| 20-100 | 10.6 |

| 20-200 | 11.5 |

| 20-300 | 11.8 |

| 20-400 | 12.3 |

Heat Treatment

| Soft Annealing °C | 650-700 |

| Cooling | Slowly |

| Hardness HB | Air, oil salt bath 500-550°C |

| Stress-relief Annealing °C | 63 |

| Cooling | Furnace |

| 1st Pre-Heating °C | up to approx. 400 in an air-circulating furnace |

| 2nd and 3rd | 780 and 1000 |

| Hardening °C | 1190-1230 |

| Quenching | Salt Bath, at least 520°C Oil, Air |

| Tempering °C | at least twice 530-560 |

| Hardness after Temperature HRC | 64-66 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Cold Work Steel (IND/USA/EUR)' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free