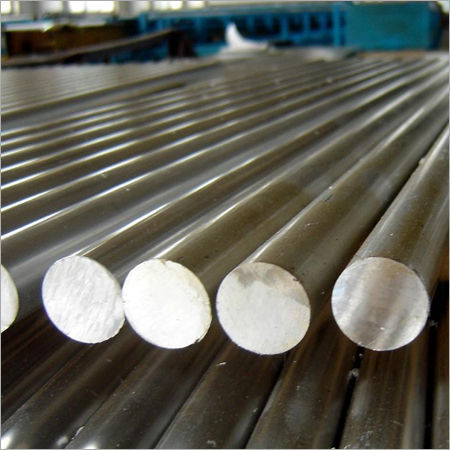

D2 Tool Steel

Product Details:

D2 Tool Steel Price And Quantity

- 192 INR

- 200 Kilograms

D2 Tool Steel Trade Information

- Mumbai Navashiva

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

Empowered by high level professionals, we are engaged in manufacturing and supplying wide assortment of D2 Tool Steel to our precious clients. It is high carbon, high chromium air hardening tool steel that is heat treatable to 60 Rc. This steel is manufactured using high grade materials and sophisticated techniques to transmit excellence to it. It is used for long run tooling applications where wear resistance is important including blanking or forming dies. Further, D2 Tool Steel is obtainable at very attractive prices for huge attraction of customer towards it.

Technical Specification

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 1.40-1.60 | 0.10-0.60 | 0.20-0.60 | 0.040max | 0.040 max | 11.00-13.00 | 1.65-2.00 | 0.70-0.100 | 0.80-1.20 |

Physical Properties

| Coefficient Conductivity at °C | 10-8W/ (m*K) |

| 20-100 | 10.6 |

| 20-200 | 11.5 |

| 20-300 | 11.8 |

| 20-400 | 12.3 |

| Thermal Conductivity at °C | W(m*k) |

| 20 | 16.7 |

| 350 | 20.5 |

| 700 | 24.2 |

Heat Treatment

| Soft Annealing °C | 840-870 |

| Cooling | Furnace |

| Hardness HB | Max. 250 |

| Stress-relief Annealing °C | Approx. 66-710 |

| Hardening °C | 1000-1050 |

| Quenching | Air, oil salt bath 500-550°C |

| Hardness after Quenching HRC | 63 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Cold Work Steel (IND/USA/EUR)' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free