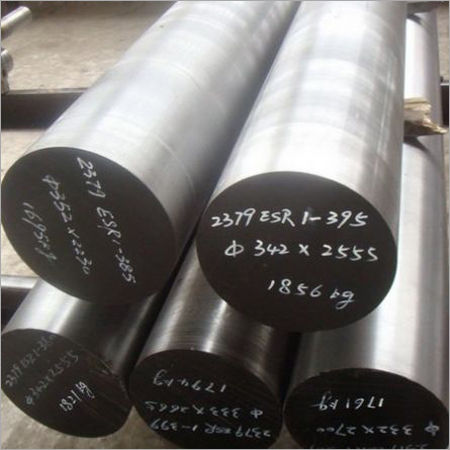

2379 Cold Work Tool Steel

उत्पाद विवरण:

2379 कोल्ड वर्क टूल स्टील मूल्य और मात्रा

- किलोग्राम/किलोग्राम

- किलोग्राम/किलोग्राम

- 200

2379 कोल्ड वर्क टूल स्टील व्यापार सूचना

- मुंबई नवशिवा

- 50-100 प्रति सप्ताह

- 1 हफ़्ता

- Yes

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

उत्पाद विवरण

2379 Cold Work Tool Steel Technical Details:

| Minimum Order Quantity | 1000 Kilogram |

| Application | Automobile Industry, Construction |

| Hardness | 57-59 HRC |

| Soft annealing Degree C | 840 - 870 |

| Hardness HB | max. 250 |

| Cooling | Furnace |

| Quenching | Air, oil or saltbath, 500-550 Degree C |

| Thermal Conductivity at Degree C | 20 - 700 |

2379 Cold Work Tool Steel Physical Properties

| Coefficient of thermal expansionat °C | 20-100 | 20-200 | 20-300 | 20-400 |

| 10-6 m/(m*K) | 10.6 | 11.5 | 11.8 | 12.3 |

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 16.7 | 20.5 | 24.2 |

Application

HCHCR D2 tool steel applicable for cold stamping or forming dies, cold forming rolls, Chipper knives, Punches, slitters, shear blades, tools, tyre shredders, trimming, cutting Threading Dies , stamping tools Etc.

Heat Treatment

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 840 – 870 | Furnace | max. 250 |

| Stress-relief annealing °C | Cooling |

|---|---|

| approx. 660-710 | Furnace |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 1000-1050 | Air, oil or saltbath, 500-550 °C | 63 |

| Tempering °C after quenching | 100 | 200 | 300 | 400 | 500 | 525 | 550 | 600 |

| HRC | 64 | 61.5 | 58.5 | 58.5 | 59 | 60 | 57 | 50 |

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

कोल्ड वर्क स्टील (IND/USA/EUR) अन्य उत्पाद

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें