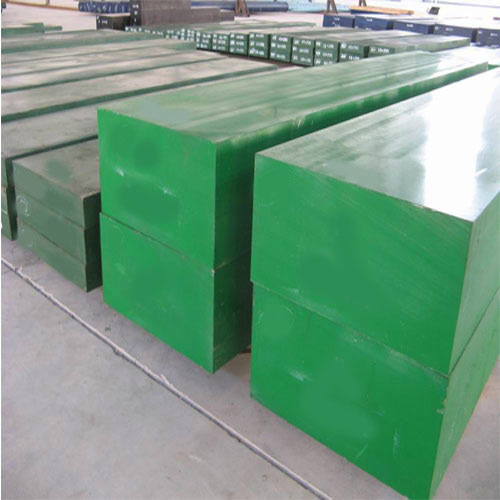

D3 Steel Block

143 INR/Kilograms

Product Details:

X

D3 Steel Block Price And Quantity

- 143 INR/Kilograms

- 200 Kilograms

Product Description

Product details

| Cooling | Furnace |

| Hardening | 840-870 Deg C |

| Hardness | Max. 235 HB |

| Hardness After Quenching | 51 HRC |

| Material Grade | HCHCR D3 |

| Quenching | Polymer or Oil |

| Soft Annealing | 710-740 Deg C |

| Technique | Hot Rolled |

| Shape | Rectangular |

| Application | Construction |

CHEMICAL COMPOSITION (Typical Analysis in %

| STANDARDS | X210CrW12 | HCHCR-D3 | DIN 2080 | AISI D3 | AFNOR Z210W12-01 | JIS SKD1 |

| C | Si | Mn | P | S | Cr |

| 2.00-2.35 | 0.10-0.60 | 0.20-0.60 | 0.030max | 0.030max | 11.00-13.00 |

PHYSICAL PROPERTIES

Coefficient of Thermal Expansion at °C | 10¯ m / (m*K) |

20-100 | 10.7 |

20-200 | 11.6 |

20-300 | 12.3 |

20-400 | 12.6 |

20-500 | 12.9 |

20-600 | 13.2 |

20-700 | 13.3 |

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 16.6 |

| 350 | 20.5 |

| 700 | 24.3 |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Die Steel Blocks' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free