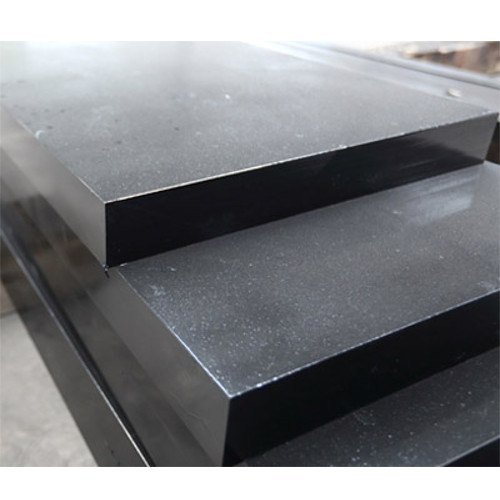

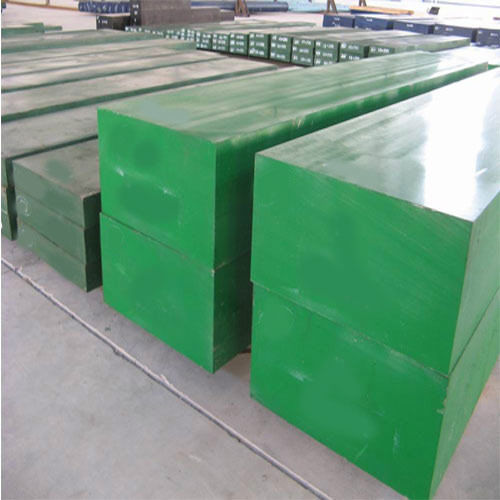

Die Steel Block

Product Details:

Die Steel Block Price And Quantity

- 200 Kilograms

- 200 INR/Kilograms

Product Description

Product details

| Minimum Order Quantity | 200 Kg |

| Coefficient of thermal expansionat Degree C | 20-700 |

| Cooling | Slowly |

| Hardening Degree C | 1000-1130 |

| Hardness after quenching HRC | 53 |

| Hardness HB | Max 240 |

| Quenching | Oil or Hot Bath,600-650 degree C |

| Soft annealing Degree C | 780-810 |

| Application | Extrusion |

| Shape | Rectangular |

Chemical Composition - (Typical Analysis in %)

| STANDARDS | X30WCrV-3 | H21 | DIN 2581 | AISI H21 | AFNOR 32CDV12-28 | JIS SKD5 |

| C | Si | Mn | P | S | Cr | W | V |

| 0.26-0.36 | 0.15-0.25 | 0.20-0.40 | 0.003 max | 0.030max | 3.00-3.75 | 8.50-10.00 | 0.30-0.60 |

| USA | France | Germany | China | Japan | England | Sweden |

| AISI / SAE | AFNOR | DIN, WNr | GB | JIS | BS |

|

| H21 / T20821 | X30WCrV9 | X30WCrV93 / 1.2581 | 3Cr2W8V | SKD5 | BH21 | 2730 |

Physical Properties:

| Coefficient of Thermal Expansion at °C | 10 m / (m*K) |

| 20-100 | 11.2 |

| 20-200 | 11.9 |

| 20-300 | 12.2 |

| 20-400 | 12.5 |

| 20-500 | 12.8 |

| 20-600 | 13.0 |

| 20-700 | 13.2 |

| Thermal Conductivity at °C | W / (m*K) |

| 100 | 27.0 |

| 400 | 29.8 |

| 675 | 29.1 |

| Tempering°C after quenching | 100 | 210 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 49 | 49 | 49 | 49 | 51 | 51 | 50 | 46 | 36 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Die Steel Blocks' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free